IMAGINING A PLASTIC-LESS FUTURE

Allan Maynard, MSc. – January 5th, 2021

Home efforts are a good start. However – to solve the complex and overwhelming issue of plastic pollution, there is a dire need for solutions based on technology, for more regulation of the plastic and packaging industries and, in the long term, a comprehensive evaluation of how we evaluate economic success (linear vs. circular economy).

HOME EFFORTS – When my wife Margrit and I finished university in 1971, we spent a year travelling around Europe and Morocco. We would do 2 to 4 week trips followed by a return to Margrit’s birth-place and our declared ‘home base’ of Bassersdorf, Switzerland (near Zurich). After weeks of camping we were grateful to enjoy home cooked dinners and sleep in real beds. We stayed with Margrit’s aunts – Aunt Lydia and Aunt Martha.

Having lived through the scarcities during the Great Depression and World War II, these two ladies seemingly never threw anything away. They would wash and save even the smallest pieces of aluminum foil and plastic wrap. Plastic bags were rare and seen as a gift for storing food. They would be used and reused until they were worn out. They had a small refrigerator and thus shopped frequently, walking to the village bakery and to other stores dedicated to certain products. Nothing was packed in plastic. No food was ever wasted. These 2 rosy-cheeked ladies provided one of the best examples I have seen of the 3 Rs of minimizing household waste – REDUCE, RECYCLE, REUSE.

Learning from Aunt Martha and Aunt Lydia – Certainly, most of society want to do more to combat plastic waste. There’s a general sense of frustration that recycling as it exists today, is not the solution it was marketed to be. Because of enhanced societal awareness, there is now a plethora of web sites dedicated to providing advice for reducing plastics use in our homes. The 3 Rs – noted above is now expanded to 4 Rs – Reduce, Reject (or refuse), Reuse, and Recycle.

It is relatively easy for most households to reduce plastic waste with some basic steps – here are but a few tips:

IS TECHNOLOGY THE ANSWER? – The short answer – unlikely but it’s complicated. Technology initiatives are centered around 3 considerations – 1) Making plastic that is biodegradable, 2) Making plastic that can be more successfully recycled and 3) Making recycling more successful than it is today. A brief summary of these:

- 1. Biodegradable Plastic – Biodegradable plastics can in theory, be broken down by microbes. Biodegradable plastics or bio-plastics are made from plant materials (starch or cellulose), rather than fossil fuels. There are a number of possibilities on the market and under research.

The big question though – even with these products – what does biodegradable really mean? It does not mean they can go to backyard compost boxes or to to landfills under the expectation they will degrade. What’s required rather, is an industrial scale composting system. Such systems are becoming more and more prominent in dealing with food waste. From coffee cups to sandwich packaging to takeaway containers, putting food in compostable plastics means that – in an ideal world, the plastic and any food waste still stuck to it can be composted together. It’s a triple win: reducing the amount of regular plastic being sent to landfill, preventing recycling from being contaminated with food, and at the same time making sure food waste is returned to the soil, rather than being left to rot in landfill where it will release methane.

The main issue though is that food waste pickup and subsequent industrial composting, while quite widespread in Europe (and some provinces in Canada), is not as prevalent as it could be in North America and in many developing countries.

- New plastics that can be continuously recycled – A previous article outlined how few of the plastics in use are recycled. Moreover, the recycled plastic material is of lower quality. Even PET – the most recycled form of plastic (used in beverage bottles) is only recycled at a rate of about 30%.

Now research is underway to produce plastics that can be recycled over and over without a resulting loss of quality. For example, the creation of a new material, called polydiketoenamine, or PDK, was reported in the journal ‘Nature Chemistry’. This formulation along with other research is showing considerable promise but it’s too early to assess commercial viability.

- Improving recycling – Today, recycling centers rely largely on mechanical processes, which consist of crushing the plastic into flakes, which are then processed and transformed into plastic granules. These granules are then, in theory, mixed with virgin plastics. It should be possible to manufacture new beverage bottles composed of at least 50 to 70 percent recycled plastic. The difficulty is that there are simply too many types of plastic on the market. Thus, sorting prior to recycling is the main limiting aspect of all recycling programs.

Better sorting – In Europe an initiative called “Project Holy Grail’ is working on much better systems for sorting waste. Postage stamp sized watermarks on packaging—which are not visible to the naked eye—make it possible to effectively sort the material into specific waste streams. With this new technology, it becomes possible to separate materials more accurately. The waste plastic can then be more effectively recycled based on the chemistry of that specific material. Again – this is in a development phase and not yet commercialized.

Waste needs to be sorted before recycling.

Chemical technology – Some in the industry suggest that chemical recycling may also provide an answer. This is very much at the research or pilot stage. The process would involve pyrolysis, which consists of heating the plastic to a high temperature to obtain a hydrocarbon product, followed by material separations into separate chemical components, followed then by re-polymerization.

GOVERNMENT NEEDS TO STEP IN – it has become clear to me that individual action on the home front along with developing technologies that are still at the research stage, will not provide all the solutions needed to deal with plastic pollution. It is my view that governments around the world need to exert more control. There is broad societal support for doing so.

Plastics impose a massive untaxed externality upon society, estimated by the Carbon Tracker and other sources at about $1,000 per tonne ($350bn a year) from resulting air pollution, health costs, collection costs, and ocean pollution. Policymakers, especially in Europe, are implementing much more stringent regulatory regimes using five key tools — taxation, design rules, bans, targets, and infrastructure. However, there is a huge and undoubtedly expected push back from industry on these initiatives. According to the Carbon Tracker report, there is a stark contrast between the plans of the petrochemical industry and the threat of imposed restrictions leading to lower growth. “The petrochemical industry already faces huge overcapacity, but is planning to spend a further $400bn for new capacity. Unless stopped, this will result in continued low prices and significant stranded assets”. (Carbon Tracker)

Fortunately – At least 127 countries have now imposed some sort of ban on single use plastic, even though there as been a relaxation of enforcement during the CoVid crisis. Most European countries now ban such products. Canada will ban the use of all single use plastic by the end of 2021. A few US states also have bans but it’s far from nation-wide. Kenya likely has the strictest regulations of all where citizens can face jail time for breaking the single use plastic laws.

In addition to bans – there are now proposals to force the plastic industry to take more responsibility for the waste their products produce. The most effective plans would require industry to pay for the disposal of plastic waste that cannot be recycled. For example – the European Union plans tax of about $1,000 US per tonne of product The plan also includes rules obliging all plastic packaging to be recyclable, and to set targets for the share of recyclates in packaging.

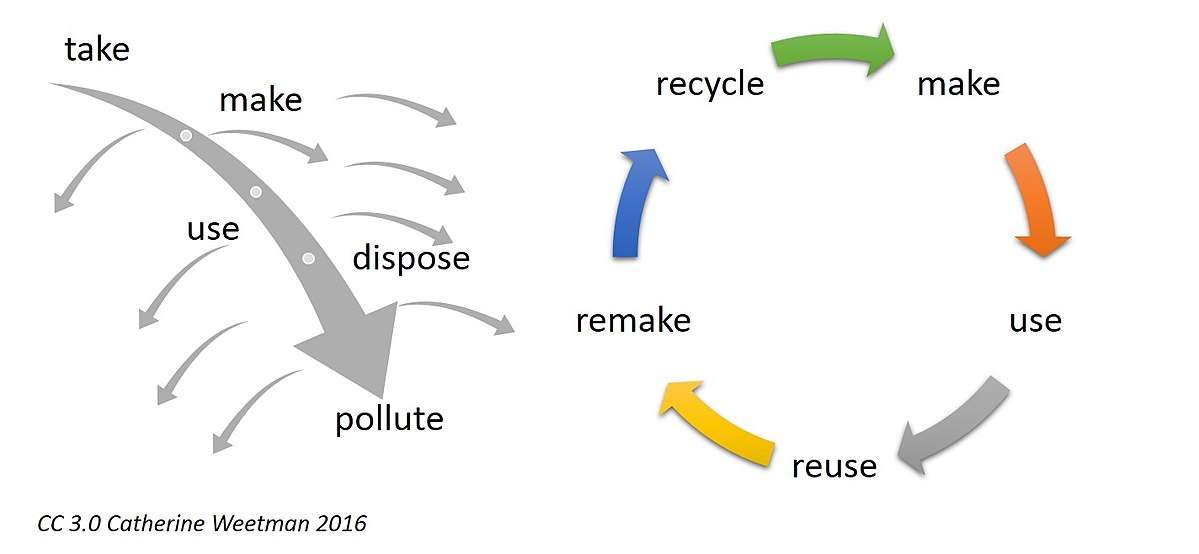

A CIRCULAR ECONOMY – The issue of plastic pollution in our environment is a clear example of the need to completely re-think global economies and how we measure success that is sustainable. GDP (Gross Domestic Product) is the standard used around the world but it does not provide information about the overall wellbeing of a country since activities that are detrimental (like waste, deforestation, strip mining, over-fishing, prison populations) actually (and strangely) increase today’s GDP. In my opinion, it is vital that we move towards a circular economy as an alternative to a traditional GDP based linear economy (make, use, dispose).

This applies very clearly for plastics in that we keep resources in use for as long as possible, extract the maximum value from them whilst in use, then recover and regenerate products and materials at the end of each service life. Yoni Shiran, lead author of ‘Breaking the Plastic Wave’ claims “There are huge benefits in the change from the current linear system to a more circular one. You can have all the functionality of plastics but at half the capital cost, half the amount of feedstock, 700,000 additional jobs and 80% less plastic pollution.” I believe this claim is possible to achieve.

REFERENCES

Can we break our addiction to plastic – Financial Times – October 30, 2019

Closed loop recycling of plastics enabled by dynamic covalent diketoenamine bonds. Nature Chemistry. April 22, 2019

The future is not in plastics. Carbon Tracker, Sept 4, 2020

Holy grail 2.0 is launched – Recycling Magazine 08/09/2020

Good information about recycling

https://www.ellenmacarthurfoundation.org

Excellent resource on all aspects of the plastics issue and about a circular economy

http://www.greeneducationfoundation.org/nationalgreenweeksub/waste-reduction-tips/tips-to-use-less-plastic.html

For tips on reducing plastics on our homes

https://www.goodhousekeeping.com/home-products/g31291481/eco-friendly-products/

One example web site that promotes eco-friendly products. There are many such web sites for those interested and I am not able to verify how good some of these items are. It just shows that a number of enterprises are working on resolutions.

FINALLY – FOR LITTLE COMIC RELIEF – Some photos of ridiculous packaging that should be easy to avoid. Maybe not so funny!!!

We have always been amazed at the kind of packaging pictured when we shop at the large supermarket chains in the UK, ……the small shops don’t have that kind of packaging at all it seems …….just an observation

A plastic-free future is a good idea. Thank you ????

Wonderful is plastic-less future. Thank you ????????